Why Engineers Choose Membrane Switches for Their High Performance and Long Life

Why Engineers Choose Membrane Switches for Their High Performance and Long Life

Blog Article

The Ultimate Resource on Membrane Changes: Design, Functionality, and Applications

Membrane changes offer as an intriguing junction of design and performance, playing an essential role in modern-day user interfaces across different sectors. As we check out the diverse applications of membrane switches, it ends up being obvious that their flexibility and longevity are critical in atmospheres ranging from medical care to consumer electronics.

Comprehending Membrane Buttons

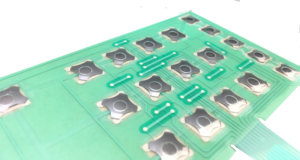

Membrane layer switches are a kind of user interface innovation commonly used in various electronic devices, identified by their thin, versatile design and capability. These buttons consist of multiple layers that consist of visuals overlays, adhesive layers, and wiring, enabling a portable and reliable user interface for customers. They can be found in home appliances, clinical gadgets, and commercial control panels, providing a dependable method for individual interaction.

Among the key benefits of membrane layer buttons is their ability to stand up to contaminants such as dust and wetness, making them appropriate for settings where sturdiness is crucial. Their inconspicuous style permits smooth assimilation into different applications, while the personalized visuals overlays enhance individual experience by providing clear visual comments. Additionally, membrane switches can fit a range of modern technologies, such as responsive feedback and backlighting, further boosting their functionality.

The production process for membrane changes usually involves screen die-cutting, printing, and lamination strategies, making certain accuracy and consistency in manufacturing. Overall, membrane switches represent a effective and functional service for modern-day digital gadgets, combining functionality with aesthetic appeal in individual interface layout.

Key Parts and Style Aspects

A selection of essential components and layout elements collaborated to develop an effective membrane layer button. At the core, the visuals overlay serves both visual and practical functions, providing an user-friendly interface while protecting interior parts from ecological factors. The selection of products, usually polyester or polycarbonate, influences durability and responsive comments.

Beneath the overlay, the glue layer guarantees the button adheres safely to the substratum, which can be metal, glass, or plastic. The spacer layer is critical, as it keeps the essential space in between the overlay and the circuit layers, enabling reliable actuation. Membrane Switches. Circuit traces, generally made from conductive ink or adhesive, are published on a versatile substrate, making it possible for electrical signals to be transferred when stress is used

Style factors to consider also include the arrangement of tactile domes or embossing that give physical feedback to the individual, boosting the overall experience. Additionally, the design and spacing of the switches should be enhanced for convenience of use, ensuring that customers can navigate the user interface intuitively. In general, these components and style components work synergistically to develop a trusted, practical membrane layer button customized to specific applications.

Capability and Operation Device

At the heart of effective functionality for membrane switches exists their operational mechanism, which facilitates customer interaction through an easy yet effective layout. These buttons operate the concept of stress activation, where a user uses force to a marked area of the switch (Membrane Switches). This activity compresses the layers of the button, completing an electric circuit that sends out a signal to the connected tool

The construction normally includes a leading visuals layer, a look at this now glue spacer layer, and a lower circuit layer, which jointly create a durable user interface. When pressure is applied, the top layer falls down against the lower circuit layer, enabling conductive traces to attach. This style not only allows clear tactile comments yet likewise ensures sturdiness and integrity, as the buttons are typically resistant to dust and wetness.

In addition, the convenience of membrane changes enables for integration with numerous modern technologies, consisting of LED signs and microcontrollers, improving their capability. By providing a structured interface that reduces mechanical wear, membrane switches over remain a preferred option in applications ranging from consumer electronic devices to commercial equipment, guaranteeing ideal performance and individual fulfillment across varied atmospheres.

Kinds Of Membrane Layer Switches

One more substantial category is lit up membrane layer switches, which integrate backlighting to improve exposure in low-light problems. These buttons are usually made use of in control panels and dashboards where clear visibility is vital.

Furthermore, there are custom-made membrane switches made to fulfill specific dimensional, visual, and functional demands. These customizations can consist of special forms, colors, and formats, allowing for seamless assimilation into different gadgets.

Applications Throughout Different Industries

How do membrane layer buttons improve performance across varied industries? These versatile elements are indispensable to many applications, providing streamlined individual interfaces and durable performance. In the medical industry, membrane layer buttons play a vital function in tools such as diagnostic devices and person tracking systems, where dependability and convenience of cleaning are extremely important. Their capacity to stand up to rough atmospheres makes them excellent for lab tools and surgical gadgets.

In the auto sector, membrane layer buttons are generally used in control panels and control board, offering user-friendly controls that enhance vehicle driver safety and benefit. The consumer electronic devices sector additionally benefits from their light-weight and adjustable functions, making it possible for sleek layouts for smartphones and home appliances.

Furthermore, membrane layer buttons locate applications in industrial automation, where they contribute to efficient equipment procedure and monitoring systems. internet Their resistance to dust and dampness makes certain capability in requiring problems (Membrane Switches). Additionally, the food and beverage sector utilizes membrane switches for equipment control, where hygiene and toughness are vital

Final Thought

To conclude, membrane layer switches represent a crucial development in interface technology, identified by their unique style and functionality. Their vital elements, including graphic overlays and circuit traces, add to their functional performance with stress activation. The flexibility of membrane switches over facilitates their application across varied industries, from clinical devices to customer electronic devices. This comprehensive understanding enhances the value of membrane buttons in improving item functionality and longevity in contemporary technological settings.

Membrane layer switches serve as an intriguing junction of style and performance, playing an essential role in modern individual interfaces throughout different markets.Membrane buttons are a type of user interface innovation widely utilized in different electronic tools, identified by their thin, adaptable style and performance.At the heart of efficient capability for membrane switches exists their operational system, which promotes user communication with a basic yet reliable layout. These switches operate on the concept of stress activation, where a customer uses pressure to a marked location of the switch.In final thought, membrane switches over stand for an essential advancement in user interface technology, characterized by their one-of-a-kind design and performance.

Report this page